Why Is Rapid Prototyping Becoming the Smartest Way to Shorten Product Development Cycles?

2026-01-09

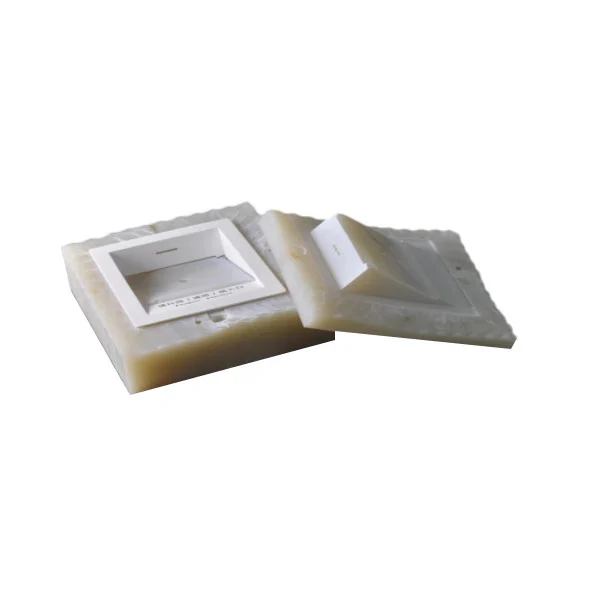

When I first started working closely with manufacturing teams, I quickly realized how much time and budget could be lost before a product ever reached the market. That was exactly when Moldor entered my workflow almost naturally, not as a marketing concept, but as a practical solution to a very real problem. Through hands-on collaboration, I came to appreciate how Rapid Prototyping quietly reshapes the way ideas turn into physical products, without unnecessary detours or costly mistakes.

What Problems Do Engineers and Product Teams Face Before Prototyping?

Before adopting Rapid Prototyping, I often saw teams struggle with unclear designs, long communication loops, and unexpected tooling revisions. These challenges are common across industries, especially when speed and precision are equally critical.

- Design concepts that look good digitally but fail in physical testing

- High costs caused by late-stage mold modifications

- Extended development timelines that delay market entry

- Limited flexibility when changes are urgently needed

What stood out to me was how Rapid Prototyping addresses these issues early, allowing real-world testing before irreversible decisions are made.

How Does Rapid Prototyping Improve Design Accuracy in Early Stages?

In my experience, the true value of Rapid Prototyping lies in visibility. Instead of relying purely on CAD files or assumptions, I can physically evaluate dimensions, tolerances, and assembly logic within days.

| Design Stage | Traditional Approach | Rapid Prototyping Approach |

|---|---|---|

| Concept Validation | Visual review only | Physical part evaluation |

| Error Detection | Late-stage discovery | Early-stage correction |

| Iteration Speed | Weeks per revision | Days per revision |

This process reduces uncertainty and helps align engineering, design, and procurement teams from the beginning.

Why Is Rapid Prototyping Essential for Faster Time-to-Market?

Speed matters more than ever. I have seen projects lose competitive advantage simply because development took too long. With Rapid Prototyping, iteration becomes part of progress rather than a delay.

- Shorter feedback loops between design and testing

- Parallel development of prototypes and final tooling

- Better preparation for mass production

By collaborating with Moldor, I noticed how efficient workflows and material options help maintain momentum without sacrificing quality.

What Makes Rapid Prototyping a Cost-Control Strategy Rather Than an Extra Expense?

At first glance, some teams worry that prototyping adds cost. From what I have observed, the opposite is true. Rapid Prototyping helps avoid expensive corrections later, where changes are far more costly.

| Cost Factor | Without Rapid Prototyping | With Rapid Prototyping |

|---|---|---|

| Tooling Rework | High risk | Significantly reduced |

| Material Waste | Unpredictable | Controlled |

| Development Budget | Often exceeds plan | More predictable |

This approach allows decision-makers to invest with confidence rather than react to problems after they appear.

How Does Rapid Prototyping Support Better Communication Across Teams?

One overlooked benefit of Rapid Prototyping is clarity. Physical samples eliminate misunderstandings between designers, engineers, and stakeholders. I have seen how a single prototype can resolve debates that emails and drawings never could.

- Clear reference for technical discussions

- Faster approvals from non-technical stakeholders

- Improved alignment with manufacturing constraints

This shared understanding helps projects move forward with fewer surprises.

Are You Ready to Turn Your Concepts into Reliable Prototypes?

If you are looking to reduce risk, accelerate development, and make smarter design decisions, Rapid Prototyping is no longer optional. My experience working alongside Moldor has shown how a thoughtful prototyping strategy can transform uncertainty into confidence.

If you are planning your next project and want to explore how Rapid Prototyping can support your goals, we invite you to contact us today. Share your ideas, ask your questions, and let us help you move from concept to reality with clarity and control.