What Makes the Segmented Asphalt Saw Blade the Right Choice for Asphalt Cutting?

2025-07-07

In construction, road maintenance, and infrastructure projects, few tasks are as demanding as cutting through asphalt. The surface itself is abrasive, unpredictable, and requires equipment that can perform consistently under pressure. That’s where the Segmented Asphalt Saw Blade proves its value, offering a professional cutting solution that has been refined through extensive research, engineering adjustments, and rigorous testing.

This saw blade is specifically designed for cutting asphalt but offers remarkable versatility for handling other challenging materials, including high reinforced concrete, masonry, floor tiles, and a wide range of building materials. Its performance is not a coincidence but the result of countless hours invested by our engineers to create the ideal material ratio, segment structure, and overall durability to meet the demands of today’s job sites.

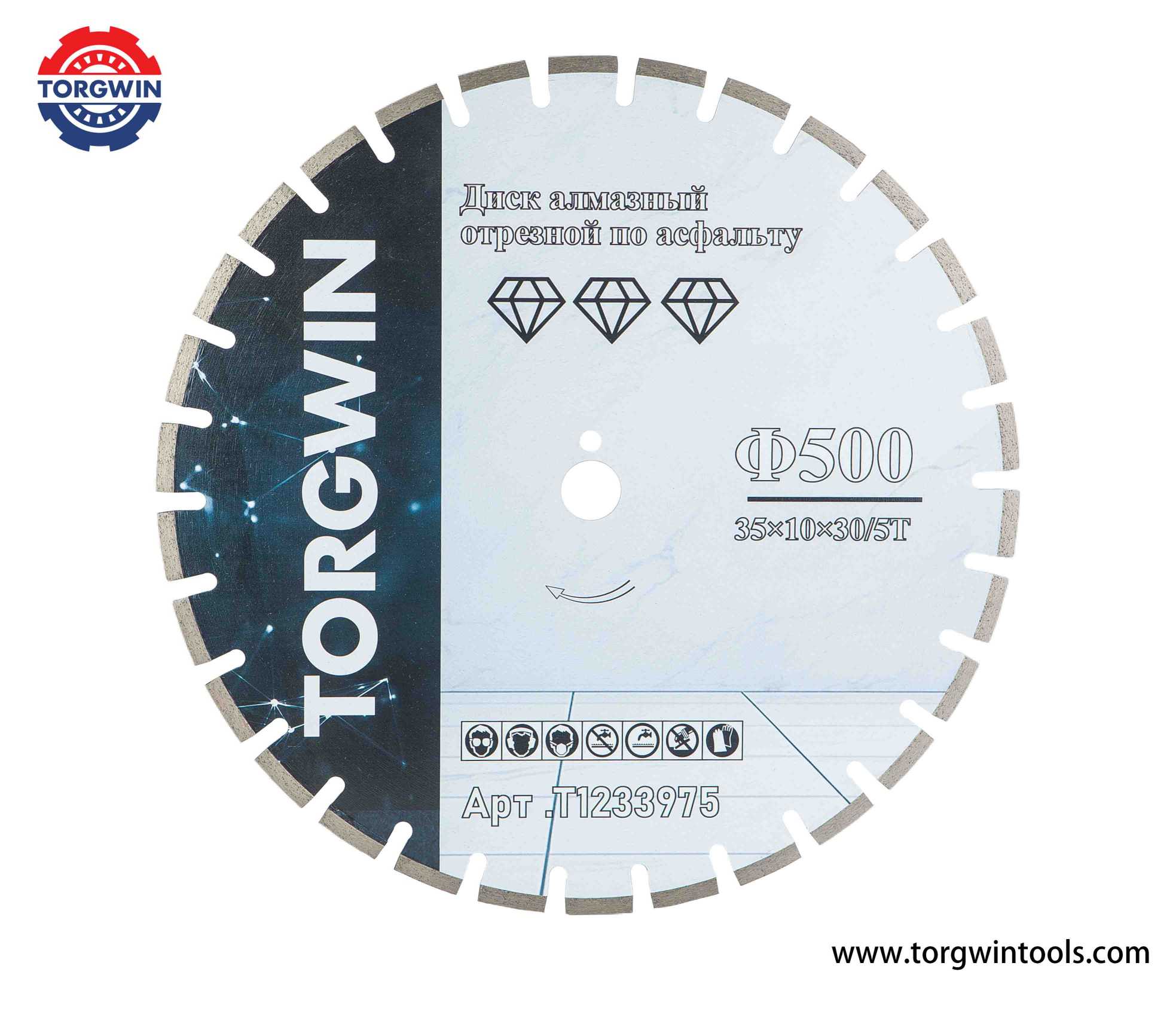

The Segmented Asphalt Saw Blade is available in multiple sizes, including 350 mm and 400 mm diameters, with a standard 25.4 mm bore. The blade thickness ranges from 2.2 to 2.4 mm, while the segment height reaches 15 mm, providing the robustness needed for heavy-duty cutting operations. One of the standout features of this blade is its laser soldered segment, a technology that significantly enhances blade longevity and ensures a stable, consistent cutting performance throughout its service life. Laser soldering not only extends the blade’s durability but also reinforces safety by reducing the risk of segment detachment during intense cutting sessions.

Professionals who work with asphalt understand the importance of cutting precision and operational efficiency. Through extensive field testing, our engineers have confirmed that this blade delivers cutting performance at least 30 percent higher than comparable products in the market. That means faster project completion times, reduced tool replacement costs, and better results on the toughest materials.

Another key advantage of this saw blade is its compatibility with both wet and dry cutting methods. Dry cutting is ideal for situations where speed and blade life are priorities, offering a longer lifespan for the tool. On the other hand, wet cutting produces a cleaner, sharper cut by minimizing friction and reducing dust, which is particularly beneficial for improving the smoothness of the finished surface and enhancing operational safety.

For blade sizes up to 300 mm, the Segmented Asphalt Saw Blade is designed with an additional hole on the enclosure. This practical detail allows the worker to better secure the blade, preventing slipping and providing greater stability during cutting tasks, especially on uneven or unpredictable surfaces.

Every feature of this saw blade reflects a deep understanding of the real-world challenges faced by construction teams. It is a product built not only for efficiency but for reliability, safety, and long-term value. Whether cutting through asphalt roads, reinforced concrete structures, or dense masonry, the Segmented Asphalt Saw Blade provides the professional performance needed to tackle the most demanding projects with confidence.

For contractors, road repair specialists, and construction professionals looking to upgrade their cutting equipment, this blade represents the perfect combination of advanced engineering, field-tested durability, and exceptional cutting results. When the job requires precision, speed, and resilience, choosing the Segmented Asphalt Saw Blade ensures your team has the right tool to deliver quality, efficiency, and safety on every project.