Unveiling the Materials Behind the 12A Middle Glass Warm Edge Spacer

2024-05-24

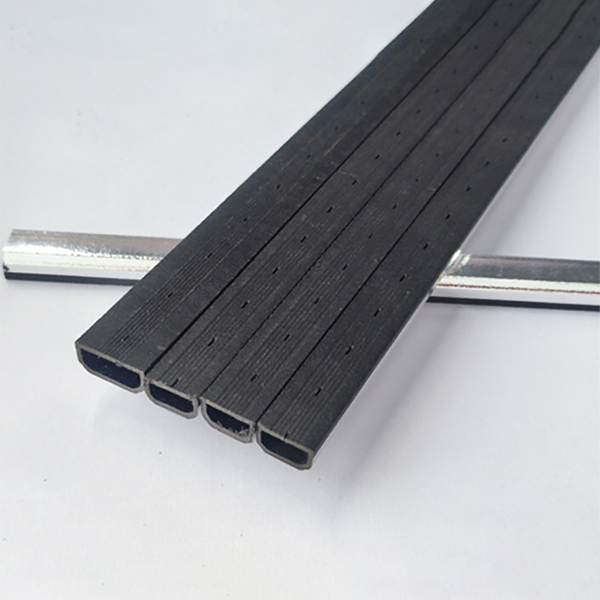

The construction industry is continuously evolving, driven by the quest for improved energy efficiency, sustainability, and performance. One of the key innovations in modern window technology is the warm edge spacer, and among them, the 12A Middle Glass Warm Edge Spacer stands out. Understanding the materials used in its construction provides insight into why it is a preferred choice for enhancing the performance of insulated glass units (IGUs).

The Role of Warm Edge Spacers

Before diving into the materials, it’s essential to grasp the role of warm edge spacers. These spacers are placed between the panes of glass in an IGU, reducing heat transfer and improving thermal efficiency. Traditional spacers, often made from aluminum, can conduct heat and cold, leading to energy loss and condensation. Warm edge spacers address these issues by using materials with lower thermal conductivity.

Materials Used in the 12A Middle Glass Warm Edge Spacer

The 12A Middle Glass Warm Edge Spacer is crafted from a combination of materials designed to maximize thermal performance, durability, and ease of installation.

1. Polymeric Composites:

The core material of the 12A spacer is typically a high-performance polymeric composite. These composites are chosen for their excellent thermal insulation properties. Unlike metal, polymers do not conduct heat well, which helps in maintaining the temperature inside the IGU and prevents thermal bridging.

2. Desiccants:

Within the spacer, desiccants are embedded to absorb any moisture that might seep into the IGU. Moisture control is crucial to prevent condensation, which can cloud the glass and reduce its insulating properties. The desiccant used is usually a type of silica gel or molecular sieve, both known for their high moisture absorption capacity.

3. Stainless Steel or Thin Metal Foils:

To add structural integrity without compromising thermal performance, some warm edge spacers incorporate thin strips of stainless steel or other metals with low thermal conductivity. These metals provide the necessary rigidity and support, ensuring the spacer maintains its shape and functionality over time.

4. Adhesives and Sealants:

High-quality adhesives and sealants are used to bond the spacer to the glass and ensure an airtight seal. These materials need to be flexible to accommodate thermal expansion and contraction, and durable to withstand years of exposure to sunlight and temperature variations. Butyl-based sealants are common due to their excellent adhesion and low permeability.

Why These Materials Matter

The combination of polymeric composites, desiccants, thin metal foils, and advanced adhesives results in a spacer that significantly enhances the energy efficiency of windows. Here’s how these materials contribute:

- Thermal Insulation: The low thermal conductivity of polymers and the strategic use of metals minimize heat transfer, keeping indoor temperatures stable and reducing energy costs.

- Moisture Control: Effective desiccants prevent condensation, ensuring the longevity and clarity of the glass.

- Structural Integrity: Thin metal foils provide necessary strength without compromising thermal performance, ensuring the spacer maintains its form and function.

- Durability and Flexibility: Advanced adhesives and sealants ensure long-term performance, accommodating the natural movements of the glass and spacer assembly without losing their sealing properties.

Conclusion

The 12A Middle Glass Warm Edge Spacer represents a sophisticated blend of materials designed to tackle the challenges of energy efficiency and durability in modern glazing solutions. By understanding the materials involved, we gain insight into why this spacer is a vital component in high-performance windows, contributing to sustainable building practices and enhanced indoor comfort. As the construction industry continues to prioritize energy efficiency, the role of advanced materials in products like the 12A Middle Glass Warm Edge Spacer will only become more critical.