Unveiling the Composition of SECE Color Coated Galvanized Steel Coil

2024-04-25

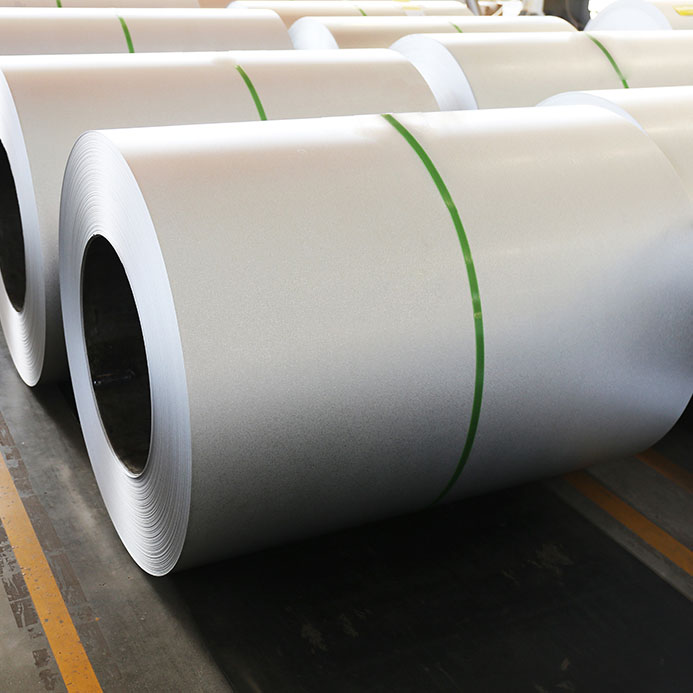

In the realm of construction, infrastructure, and industrial applications, steel reigns supreme as one of the most versatile and durable materials. Among the myriad of steel products available in the market, the SECE Color Coated Galvanized Steel Coil stands out for its exceptional properties and wide-ranging applications. But what exactly makes up this remarkable material? Let's delve into the specifics of its composition to understand its unique characteristics and benefits.

At the heart of the SECE Color Coated Galvanized Steel Coil lies a meticulous blend of materials engineered to deliver superior performance in various environments. Here's a breakdown of its key components:

1. Galvanized Steel Substrate: The foundation of the SECE Color Coated Galvanized Steel Coil is high-quality galvanized steel. Galvanization involves coating steel with a layer of zinc to protect it from corrosion and rust. This zinc coating acts as a sacrificial barrier, shielding the underlying steel substrate from environmental elements such as moisture, chemicals, and abrasion.

2. Color Coating: Building upon the galvanized steel substrate is a specialized color coating formulated to enhance both aesthetics and durability. The color coating is typically composed of various resins, pigments, binders, and additives. These components work synergistically to provide vibrant colors, excellent adhesion, UV resistance, and weatherability, ensuring long-lasting performance in diverse climates and applications.

3. Protective Layers: In addition to the zinc coating and color layer, SECE Color Coated Galvanized Steel Coil may include additional protective layers for enhanced performance. These layers could include primers for improved adhesion, anti-corrosion coatings for added durability, or clear coatings for extra gloss and protection against scratches.

4. Alloying Elements: Depending on specific requirements and industry standards, the steel substrate may contain alloying elements such as manganese, silicon, or aluminum. These alloying elements can enhance the mechanical properties of the steel, including strength, ductility, and formability, making it suitable for a wide range of applications.

5. Quality Control Additives: Throughout the manufacturing process, various quality control additives may be incorporated to ensure consistent performance and adherence to industry standards. These additives may include rust inhibitors, anti-fungal agents, or lubricants to facilitate processing and handling.

Understanding the composition of the SECE Color Coated Galvanized Steel Coil unveils its exceptional qualities and versatility. By combining the inherent strength and corrosion resistance of galvanized steel with advanced color coating technologies, this material offers a compelling solution for architectural, automotive, appliance, and other demanding applications.

Whether it's adding a splash of color to architectural facades, providing durable roofing solutions, or manufacturing high-performance appliances, SECE Color Coated Galvanized Steel Coil stands as a testament to innovation and excellence in the steel industry. With its carefully engineered composition and superior performance, it continues to redefine the possibilities of steel in the modern world.