Unveiling the Composition of Color-Coated Galvanized Steel Coils

2023-11-27

Introduction:

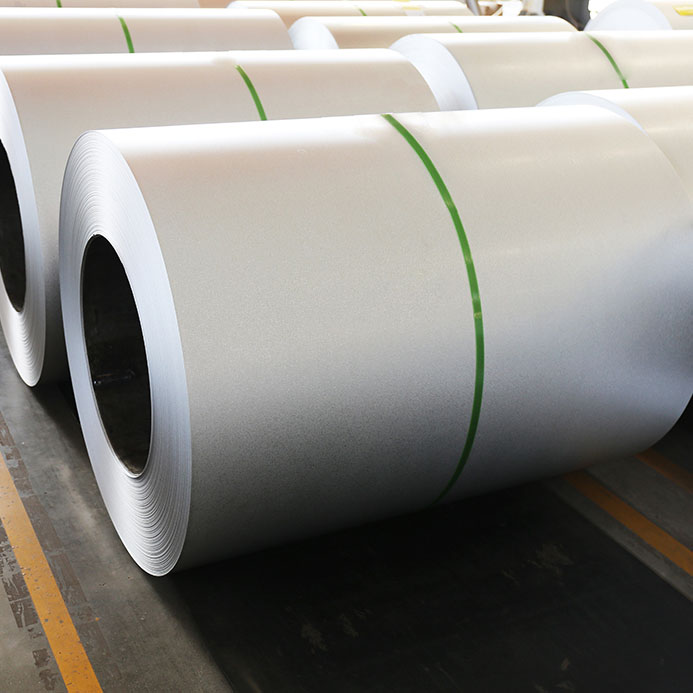

Color-coated galvanized steel coils have become a staple in various industries, offering a winning combination of durability, corrosion resistance, and aesthetic appeal. But what exactly goes into the making of these versatile coils? In this blog, we'll delve into the basic composition of color-coated galvanized steel coils, exploring the elements that make them a preferred choice in construction, automotive, and other applications.

1. Steel Substrate:

At the core of every color-coated galvanized steel coil lies a steel substrate. This is often high-quality cold-rolled or hot-dip galvanized steel. The choice of substrate influences the mechanical properties and overall strength of the coil.

2. Galvanized Coating:

Prior to color coating, the steel substrate undergoes a galvanization process. This involves immersing the steel in a bath of molten zinc, creating a protective layer that shields the steel from corrosion. The thickness of this galvanized coating is a critical factor in determining the coil's longevity and resistance to the elements.

3. Pre-Treatment Layers:

To enhance adhesion and ensure uniformity in the color coating, manufacturers apply pre-treatment layers. These layers typically consist of chemicals and conversion coatings that prepare the surface for the application of the color coating.

4. Primer:

The primer is the first layer of color that is applied to the galvanized steel. It serves as a bonding agent between the steel substrate and the topcoat. The primer enhances corrosion resistance and promotes adhesion of the subsequent layers.

5. Topcoat:

The topcoat is the outermost layer of the color-coated galvanized steel coil. It provides the desired color and adds an additional layer of protection against UV radiation, weathering, and scratches. Different types of topcoats can be used, including polyester, polyurethane, and fluorocarbons, each offering varying levels of durability and gloss.

6. Protective Film (Optional):

In some cases, a protective film may be applied over the topcoat to safeguard the steel during transportation, storage, and installation. This film is usually removed after the product is in place.

Conclusion:

Understanding the basic composition of color-coated galvanized steel coils sheds light on their robustness and versatility. From the steel substrate to the protective layers and vibrant topcoats, each element plays a crucial role in ensuring these coils meet the demanding requirements of modern construction and manufacturing. As technology advances, innovations in coating materials and application processes continue to enhance the performance and aesthetic qualities of color-coated galvanized steel, making them an enduring choice for diverse applications.