Understanding Toughened Polystyrene: A Durable and Versatile Material for Modern Applications

2025-01-03

Polystyrene (PS) is one of the most commonly used plastics in a variety of industries, ranging from packaging to consumer electronics. However, the traditional form of polystyrene, while inexpensive and versatile, is often criticized for its brittleness, making it prone to cracking and breaking under stress. To address this limitation, Toughened Polystyrene (TPS) was developed—an enhanced version of standard polystyrene designed to offer improved impact resistance without compromising its many other valuable characteristics.

In this blog, we will explore the properties, benefits, applications, and manufacturing process of toughened polystyrene and why it’s becoming an increasingly popular choice for manufacturers worldwide.

What is Toughened Polystyrene?

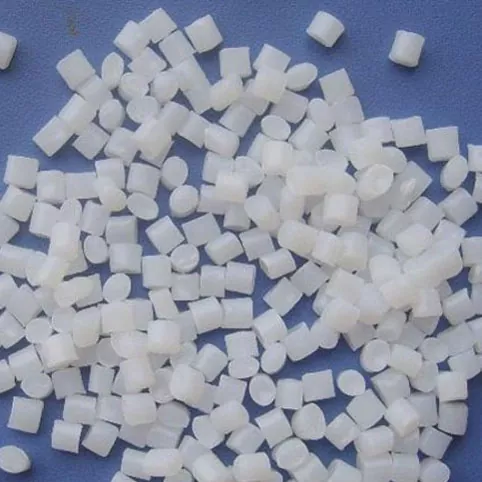

Toughened Polystyrene is a modified version of standard polystyrene, achieved by incorporating impact modifiers such as elastomers or rubber particles into the polymer matrix. This alteration improves the material's toughness, making it less brittle and more resilient to impact forces. As a result, toughened polystyrene exhibits a significantly higher resistance to cracking or breaking, even when subjected to harsh conditions.

Key Properties of Toughened Polystyrene:

1. Improved Impact Resistance:

- The most notable feature of TPS is its enhanced ability to withstand impacts. The addition of impact modifiers allows the material to absorb energy more effectively, reducing the likelihood of breakage.

2. Lightweight and Low-Density:

- Despite its added toughness, TPS remains relatively lightweight, offering a combination of strength and minimal weight, which is particularly advantageous in sectors like packaging and automotive manufacturing.

3. Excellent Surface Finish:

- TPS retains the smooth, glossy surface finish typical of polystyrene, which is desirable in aesthetic applications, such as consumer electronics and food packaging.

4. Cost-Effective:

- Like standard polystyrene, TPS is an affordable option for manufacturers looking for an impact-resistant plastic without the high costs associated with alternatives like polycarbonate or ABS.

5. Chemical and Environmental Resistance:

- Toughened polystyrene has a moderate resistance to various chemicals and environmental factors, making it suitable for both indoor and outdoor applications.

Applications of Toughened Polystyrene:

Toughened polystyrene's combination of impact resistance, low weight, and cost-effectiveness makes it a popular choice in a range of industries:

1. Packaging:

- In the packaging industry, TPS is often used for protective packaging materials, especially for fragile goods. Its superior toughness ensures that the contents remain intact even when exposed to rough handling during shipping.

2. Consumer Electronics:

- Many consumer electronics, including housings for televisions, computer monitors, and household appliances, are made from toughened polystyrene due to its durability and aesthetic qualities.

3. Automotive:

- TPS is used in automotive interior parts, such as dashboards and trim components, where both toughness and a smooth surface finish are required.

4. Medical Devices:

- The biocompatibility and ease of processing of TPS make it an attractive option for manufacturing medical device components, such as enclosures and other small parts.

5. Building and Construction:

- Toughened polystyrene is also used in building materials, including insulation panels and protective coverings, where resistance to physical stress is crucial.

Manufacturing Process:

The process of creating toughened polystyrene typically involves melt blending the base polystyrene resin with impact-modifying elastomers. The polymer is then processed using standard techniques such as injection molding or extrusion. The result is a material that retains the characteristics of traditional polystyrene but with the added benefit of enhanced toughness.

Toughened Polystyrene stands as a valuable innovation in the plastics industry, offering the same benefits as traditional polystyrene—such as cost-efficiency and ease of processing—while overcoming its brittleness. Its superior impact resistance and versatility make it suitable for a wide variety of applications across industries.