Understanding Hydrogenated Hydrocarbon Resins

2024-12-30

Hydrogenated hydrocarbon resins may sound like a complex chemical term, but they play a significant role in a wide range of industries. From adhesives to packaging, these versatile materials are essential in modern manufacturing. In this blog, we’ll explore what hydrogenated hydrocarbon resins are, how they are made, and their applications.

What Are Hydrogenated Hydrocarbon Resins?

Hydrogenated hydrocarbon resins are synthetic resins derived from petroleum-based feedstocks. They are created by hydrogenating hydrocarbon resins, which involves adding hydrogen to the resin’s molecular structure. This process improves the resin’s stability, color, and resistance to oxidation. As a result, hydrogenated resins are more transparent, durable, and environmentally stable compared to their non-hydrogenated counterparts.

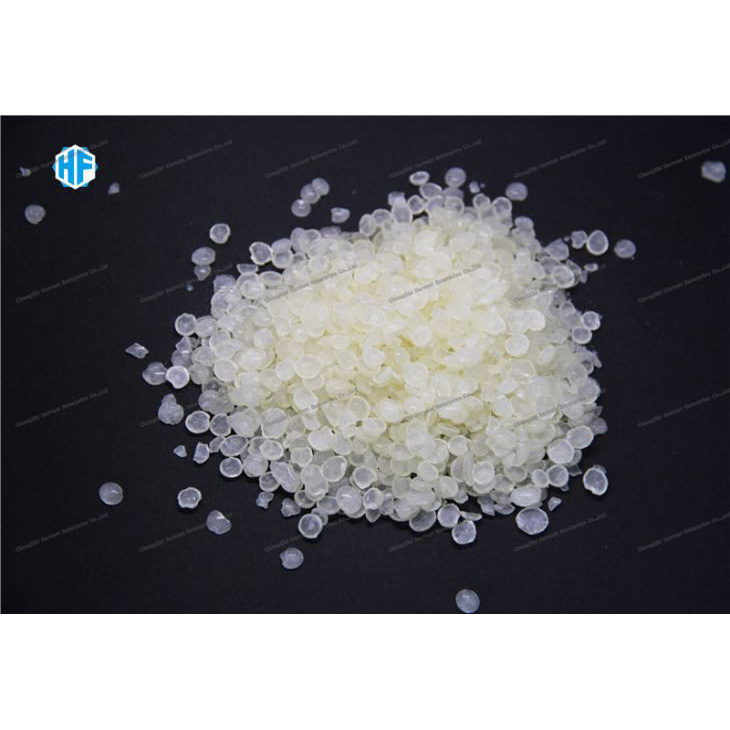

These resins typically come in forms such as granules, flakes, or powder and are soluble in various organic solvents. Their unique properties make them invaluable in applications requiring high performance and aesthetic appeal.

The Manufacturing Process

1. Feedstock Selection: Hydrogenated hydrocarbon resins are commonly made from petroleum-based materials like C5, C9, or a combination of these fractions.

2. Polymerization: The feedstock undergoes polymerization to form hydrocarbon resins with specific molecular structures.

3. Hydrogenation: In this crucial step, the resin is treated with hydrogen gas under high pressure and temperature in the presence of a catalyst. This process saturates the molecular bonds, resulting in a hydrogenated hydrocarbon resin with improved stability and reduced color.

Key Applications

Hydrogenated hydrocarbon resins are used in a variety of industries, including:

- Adhesives: Their excellent tackiness and compatibility with polymers make them ideal for hot-melt and pressure-sensitive adhesives.

- Coatings: They improve the gloss, transparency, and weather resistance of coatings used in automotive and construction.

- Packaging: Their low odor and excellent bonding properties make them suitable for food packaging applications.

- Rubber and Plastics: They enhance the performance of rubber compounds and plastic products by improving flexibility and durability.

Hydrogenated hydrocarbon resins offer a perfect balance of performance and versatility, making them a vital component in many products we use daily. As industries continue to innovate, the demand for these resins is expected to grow.