The Art and Science of Custom Sheet Metal Bending for Stainless Steel Stamping Parts

2024-07-11

Introduction

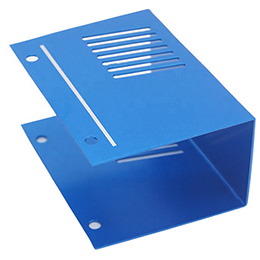

Custom sheet metal bending and stainless steel stamping parts play a crucial role in various industries, from automotive to aerospace. The ability to create precise, durable, and intricate metal components is essential for manufacturing high-quality products. In this blog, we'll explore the art and science behind custom sheet metal bending, the benefits of stainless steel stamping, and how these processes come together to create superior parts.

Understanding Custom Sheet Metal Bending

Custom sheet metal bending involves shaping metal sheets into desired forms using various techniques and machinery. This process requires a deep understanding of material properties, bending methods, and tooling. Here are the key steps in custom sheet metal bending:

1. Material Selection: Choosing the right type of stainless steel is crucial. Common grades used include 304 and 316, known for their excellent corrosion resistance and strength.

2. Design and CAD Modeling: Engineers create detailed designs using CAD software to ensure precision and accuracy. The design phase also includes considerations for bend allowances and tolerances.

3. Tooling and Equipment: Specialized tools such as press brakes, dies, and punches are used to bend the metal sheets. The choice of tooling depends on the complexity and requirements of the part.

4. Bending Techniques: Various techniques like air bending, bottoming, and coining are employed based on the desired outcome. Each method has its advantages and limitations.

5. Quality Control: Precision is critical in custom sheet metal bending. Advanced measurement tools and techniques are used to ensure that the final parts meet the required specifications.

The Role of Stainless Steel Stamping

Stainless steel stamping is a manufacturing process that involves using dies and presses to shape stainless steel into specific forms. This technique is highly efficient for producing large volumes of parts with consistent quality. Here are some benefits of stainless steel stamping:

1. Durability: Stainless steel is renowned for its strength and resistance to corrosion, making it an ideal material for stamped parts used in harsh environments.

2. Precision: Stamping allows for high levels of precision, ensuring that each part meets strict tolerances and design specifications.

3. Cost-Effectiveness: Once the initial tooling is created, stainless steel stamping becomes a cost-effective solution for mass production.

4. Versatility: Stainless steel stamping can produce a wide range of parts, from simple brackets to complex components with intricate designs.

Combining Bending and Stamping for Superior Parts

Custom sheet metal bending and stainless steel stamping are often used together to create complex parts with high precision. Here’s how these processes complement each other:

1. Initial Shaping: Stamping can be used to create the basic shape of the part quickly and accurately.

2. Secondary Operations: Custom bending can then refine the stamped part, adding intricate bends and details that stamping alone cannot achieve.

3. Consistency and Quality: Combining these processes ensures that each part is not only precise but also consistent across large production runs.

Conclusion

Custom sheet metal bending and stainless steel stamping parts are essential for producing high-quality, durable components used in various industries. By understanding the intricacies of these processes and their benefits, manufacturers can create superior parts that meet the stringent demands of modern applications. Whether you’re in the automotive, aerospace, or any other industry, leveraging these advanced techniques can give you a competitive edge.