Revolutionizing Manufacturing with Intelligent Factory Supply Automated Edge Banding Cell

2024-07-02

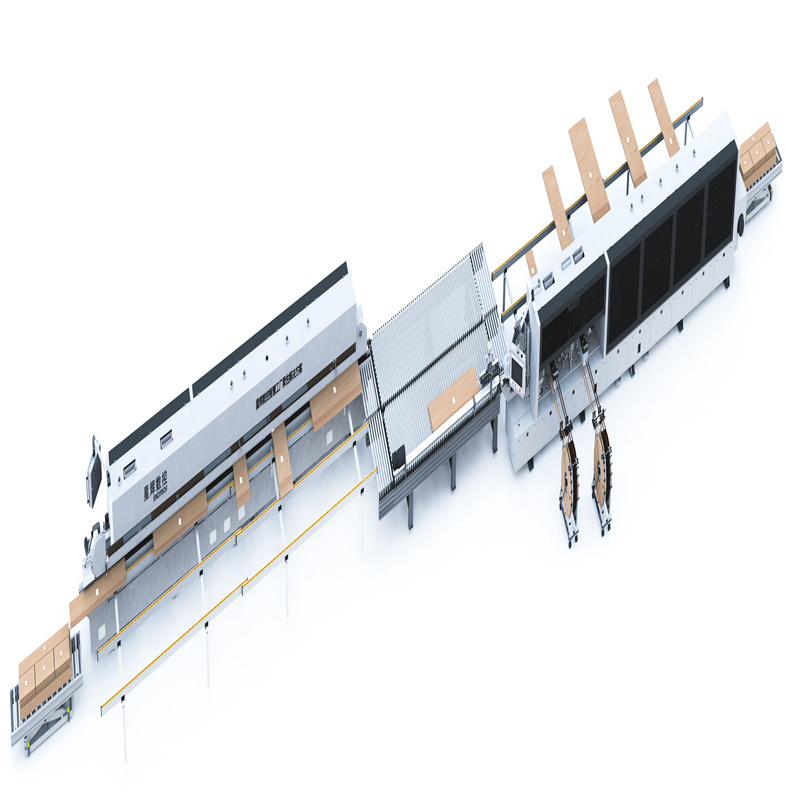

The manufacturing landscape is evolving rapidly, and the integration of advanced automation technologies is at the forefront of this transformation. Among the notable advancements is the Intelligent Factory Supply Automated Edge Banding Cell, a cutting-edge solution designed to enhance efficiency, precision, and productivity in the manufacturing process. This blog explores how this innovative technology is revolutionizing the manufacturing industry.

What is an Automated Edge Banding Cell?

An edge banding cell is a specialized unit within a manufacturing facility that applies edging to the sides of materials, typically wood or laminate, to enhance their appearance and durability. Traditional edge banding processes involve manual labor or semi-automated machinery. However, the Intelligent Factory Supply Automated Edge Banding Cell takes this process to the next level by integrating advanced automation and intelligent controls.

Key Features and Benefits

1. Precision and Consistency

The Intelligent Factory Supply Automated Edge Banding Cell employs state-of-the-art sensors and control systems to ensure precise application of edge bands. This precision leads to consistent quality across all products, reducing the likelihood of defects and rework.

2. Increased Efficiency

Automation significantly speeds up the edge banding process. The automated cell can operate continuously with minimal human intervention, leading to increased throughput and shorter production cycles.

3. Reduced Labor Costs

By automating the edge banding process, manufacturers can reduce their reliance on manual labor. This not only lowers labor costs but also minimizes the risk of human error, further enhancing product quality.

4. Enhanced Flexibility

The Intelligent Factory Supply Automated Edge Banding Cell is designed to handle a wide range of materials and edge banding types. This flexibility allows manufacturers to easily adapt to different production requirements and market demands.

5. Integration with Smart Manufacturing Systems

One of the standout features of this automated edge banding cell is its ability to integrate with other smart manufacturing systems. This integration enables real-time monitoring, data collection, and analysis, providing valuable insights for optimizing the entire production process.

Impact on the Manufacturing Industry

The adoption of the Intelligent Factory Supply Automated Edge Banding Cell is driving significant changes in the manufacturing industry. Companies that implement this technology can expect to see:

- Improved Product Quality: Consistent and precise edge banding results in higher-quality products that meet stringent industry standards.

- Faster Time-to-Market: Increased production efficiency allows manufacturers to bring products to market more quickly, giving them a competitive edge.

- Cost Savings: Reduced labor costs and minimized waste contribute to overall cost savings, improving the bottom line.

- Sustainable Practices: Automation reduces material waste and energy consumption, supporting more sustainable manufacturing practices.

Conclusion

The Intelligent Factory Supply Automated Edge Banding Cell represents a significant advancement in manufacturing technology. By offering precision, efficiency, flexibility, and integration capabilities, it is revolutionizing the way manufacturers approach edge banding processes. As the industry continues to embrace automation, the benefits of this innovative solution will become increasingly evident, driving progress and growth in the manufacturing sector.