Common Challenges in the Injection Molding Process of PET Preforms for Water Bottles

2024-06-27

The injection molding process for PET preforms used in water bottle production is complex and requires precision to ensure high-quality results. Despite advancements in technology, several challenges can arise during the process, impacting the efficiency, quality, and consistency of the final products. Here are some of the common challenges faced during the injection molding process of PET preforms for water bottles:

1. Material Handling and Drying

Moisture Sensitivity:

- PET Resin: PET is hygroscopic and absorbs moisture from the environment. If the resin is not properly dried before molding, it can lead to defects such as hydrolysis, which weakens the material and results in poor-quality preforms.

Drying Process:

- Drying Parameters: Ensuring the correct temperature and drying time is critical. Inadequate drying can cause issues like poor transparency and structural weaknesses.

2. Temperature Control

Melt Temperature:

- Consistency: Maintaining a consistent melt temperature is essential for uniform preform quality. Variations can cause defects such as incomplete filling, crystallization issues, or thermal degradation of the PET.

Hot Runners:

- Temperature Regulation: Hot runner systems must be precisely controlled to ensure even temperature distribution and prevent issues like stringing or drooling, which affect preform quality.

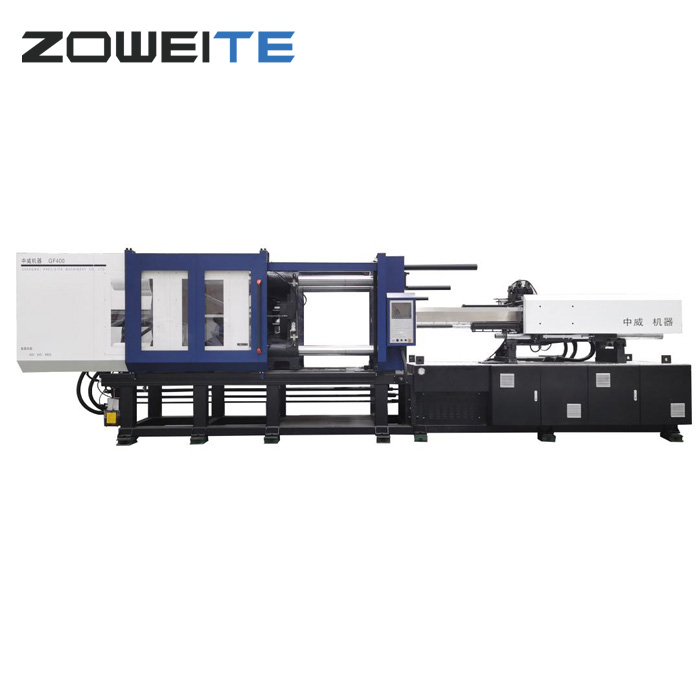

3. Injection Molding Machine Settings

Pressure and Speed:

- Injection Pressure: Incorrect pressure settings can lead to issues such as sink marks, voids, or excessive flash.

- Injection Speed: Too fast or too slow injection speeds can cause defects like flow lines, incomplete filling, or warping.

Clamping Force:

- Machine Calibration: Ensuring the correct clamping force is vital to prevent flash and ensure proper mold sealing. Too much force can damage the mold, while too little can result in poor preform formation.

4. Mold Design and Maintenance

Cooling System:

- Efficient Cooling: Proper cooling is critical for maintaining cycle times and ensuring consistent preform quality. Inadequate cooling can lead to warpage, shrinkage, and long cycle times.

Mold Wear and Tear:

- Maintenance: Regular maintenance of the mold is necessary to prevent defects such as flash, parting line wear, and dimensional inaccuracies. Wear and tear can lead to higher reject rates and inconsistent product quality.

5. Preform Design Considerations

Wall Thickness Uniformity:

- Design Consistency: Variations in wall thickness can cause issues during the blowing process, leading to uneven bottle formation and weak points.

Neck Finish:

- Precision: The neck finish must be precisely formed to ensure compatibility with caps and closure systems. Inaccuracies can lead to leakage and sealing problems.

Conclusion

The injection molding process of PET preforms for water bottles involves navigating various challenges related to material handling, temperature control, machine settings, mold design, cycle time optimization, environmental factors, and quality control. By understanding and addressing these challenges, manufacturers can improve the efficiency and consistency of their production processes, leading to higher quality and more reliable PET preforms for water bottles. Continuous monitoring, maintenance, and optimization are key to overcoming these challenges and achieving successful injection molding operations.