What are the classifications of petroleum resins?

2023-10-18

What are the classifications of petroleum resins?

Petroleum resin is a thermoplastic resin produced by the C5 and C9 fractions produced by petroleum cracking by pretreatment, polymerization, distillation and other processes. It is not a high polymer, but an oligomer with a molecular weight of 300-3000. Petroleum resins are generally not used alone, but are used together as accelerators, regulators, modifiers and other resins. What are the advantages of petroleum resin classification? What are the application fields of petroleum resin?

petroleum resin

Petroleum resin (hydrocarbon resin) is a thermoplastic resin produced by the C5 and C9 fractions produced by petroleum cracking by pretreatment, polymerization, distillation and other processes. It is not a high polymer, but a low molecular weight between 300-3000 Polymer.

source

Petroleum resin is named after the source of petroleum derivatives. It has low acid value, good miscibility, water resistance, ethanol resistance and chemical resistance, chemical stability to acid and alkali, and good viscosity adjustment and thermal stability. features. Petroleum resins are generally not used alone, but are used together as accelerators, regulators, modifiers and other resins.

Classification

Petroleum resins can generally be classified into four types: C5alphatic (aliphatic), C9aromatic (aromatic), DCPD (cycloaliphatic) and pure monomers (such as polySM, AMS (alphamethylstyrene) and other products) , and its constituent molecules are all hydrocarbons, so it is also called hydrocarbon resin (hydrocarbon resins, HCR).

Petroleum resins are divided into aliphatic resins (C5), cycloaliphatic resins (DCPD), aromatic resins (C9), aliphatic/aromatic copolymer resins (C5/C9) and hydrogenated petroleum resins according to different raw materials. C5 hydrogenated petroleum resin, C9 hydrogenated petroleum resin.

advantage

Petroleum resin is a newly developed chemical product in recent years. Due to its low price, good miscibility, low melting point, water resistance, ethanol and chemical resistance, etc., it can be widely used in rubber, adhesives, coatings, papermaking, ink, etc. Various industries and fields.

structure

Chemical element structure model of petroleum resin:

The most widely used petroleum resins are C9 petroleum resins and C5 petroleum resins.

C9 petroleum resin

C9 petroleum resin specifically refers to a resinous substance composed of "olefins or cycloolefins polymerized or copolymerized with aldehydes, aromatics, terpenes, etc." containing nine carbon atoms.

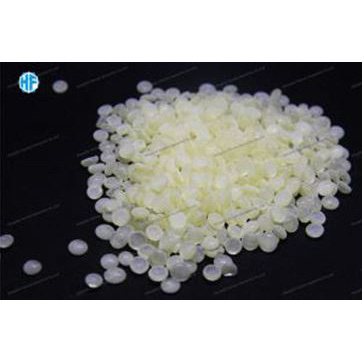

C9 petroleum resin, also known as aromatic petroleum resin, is divided into thermal polymerization, cold polymerization, tar and other types. Among them, cold polymerization products have light color and good quality, with an average molecular weight of 2000~5000. Light yellow to light brown flaky, granular or massive solid, transparent and shiny, relative density 0.97~1.04. The softening point is 80~140℃. The glass transition temperature is 81°C. The refractive index is 1.512. The flash point is 260°C. Acid value 0.1~1.0. Iodine value 30~120. Soluble in acetone, methyl ethyl ketone, cyclohexane, dichloroethane, ethyl acetate, toluene, gasoline, etc. Insoluble in ethanol and water. It has a ring structure, contains some double bonds, and has strong cohesion. There are no polar or functional groups in the molecular structure and no chemical activity. Good acid and alkali resistance, chemical resistance and water resistance. It has poor bonding performance, high brittleness and poor aging resistance, so it should not be used alone. Good compatibility with phenolic resin, coumarone resin, terpene resin, SBR, SIS, but poor compatibility with non-polar polymers due to its high polarity. combustible. non-toxic.

C5 petroleum resin

C5 petroleum resin has begun to gradually replace natural resins due to its high peel bonding strength, good fast tack, stable bonding performance, moderate melt viscosity, good heat resistance, good compatibility with polymer substrates, and low price. Resin tackifiers (rosin and terpene resins).

The characteristics of refined C5 petroleum resin in hot melt adhesives: good fluidity, can improve the wettability of the main material, good viscosity, and outstanding initial tack performance. Excellent aging resistance, light color, transparent, low odor, low volatile matter. In hot-melt adhesives, ZC-1288D series can be used alone as tackifying resin, or mixed with other tackifying resins to improve certain characteristics of hot-melt adhesives.